Advanced technologies for every application

Inspection and Quality

Identify defects before your products leave the production line. Applicable for plastic and glass bottles, jars, cans, pouches, boxes, packages and gases like CO2

Our inspection technologies find the defects, remove the fault product from the conveyor and provide you the feedback to correct the process before it’s too late to reduce waste in your production line.

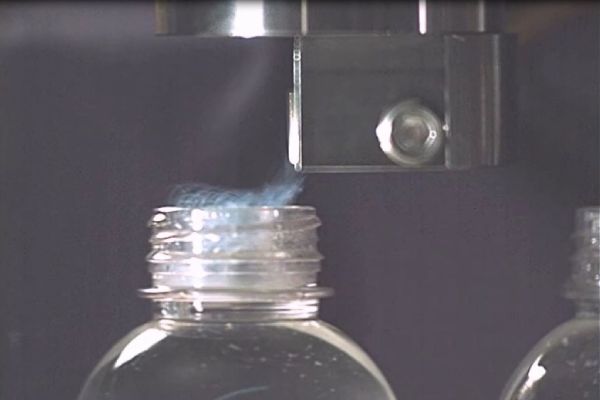

Liquid Nitrogen and CO2

The liquid nitrogen injection is used for pressurization or reduce the oxygen in the headspace of the containers to extend the shelf-life of your products and reduce the plastic content in your package.

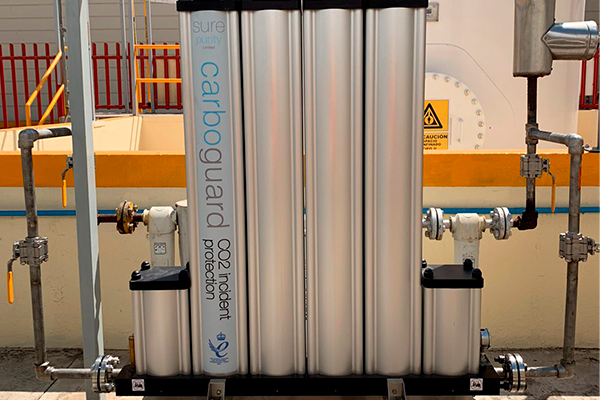

CO2 is the only industrial gas used as an ingredient in the production of carbonated beverages. We provide multi-barrier polishing filters and other CO2 technologies from the experts you can trust.

Packaging and Process

Either you are looking for a complete production line for liquids, beverages or food or want to automate a packaging process in your production line.

Our packaging solutions are the best option to increase your productivity, save energy and deliver high quality products.

Customer Satisfaction

We are focused on providing cost-effective and reliable solutions that satisfy the requirements of customer’s processes to improve the quality of their products and increase the efficiency of the production lines.

Our company is integrated by a highly trained professional team to provide you with the most advanced engineering analysis, installation assistance and effective technical and spare parts support.

Customers

Our awesome Customers we work with...

Trade Shows and Events

We will be present at several trade shows and events of the Beverage and Packaging Industry.